Helping Industry Build Big,

While Saving Time

Over-Dimension Cargo: A Case Study

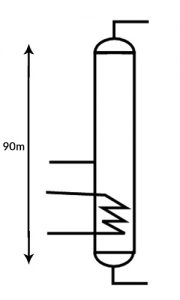

An Engineering Company in Western India was contracted to make a 90ft Industrial Separator Vessel for a Chemical Plant in South-East Asia.

When the design engineers began their calculations, they were posed with a question about

the transportation of such a tall equipment.

Pulling from our experience, we suggested a solution using logic. We suggested that if the size could be halved, it will make our task much easier.

There were examples of other heavy equipment being built that way – building in parts.

They saw merit in this simple school of thought. In fact after their research

& preliminary design calculations, they felt working on two components

simultaneously would increase the speed of construction of the separator vessel.

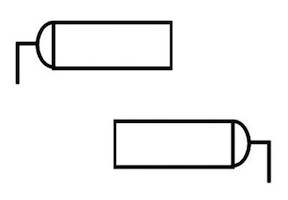

Though, the vessel size had been halved, each part was still 45 feet long. It was an unconventional size.

The transportation had to be tailored.

We used a technology-driven approach to tailor

the transportation of these separator vessels.

Multi Axle Trailer with sychronised brakesRoad Transportation from the Western India plant to sea port

Steamer BargeInland Water Transport in South-East Asia

Supersized CraneInstallation at Plant

* Pictures are for representation purpose only. These are not actual pictures from the project.

Thus, we helped install the separator vessel by bring forth the idea of building in parts to save time.